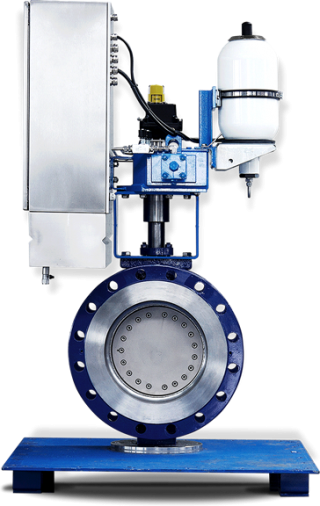

Assembly/

Commissioning

We help you with the commissioning and installation of your valve – worldwide!

We help you with the commissioning and installation of your valve – worldwide!

Our valves do not leave our premises without first being “checked out”. On our modern test benches we offer tests according to API 598, EN12266-1 and -2, ANSI FCI 70-2, ISO 5208 and also other customer specific requirements. On request also with chart recorder monitoring.

Our test stand is equipped with automated bubble and drop counter.

Over time, the requirements for a valve may change. We check with you whether the valves already installed still fit the design parameters or whether the valves should be replaced.

We document every valve we manufacture. Therefore, even after years, we can still trace back the components from which your valve was manufactured and, based on this information, offer you the appropriate spare parts. Of course, we have a large quantity of spare parts in our stock and can therefore offer you a short delivery time.

You can reach us on weekdays in the time from 8 – 16 o’clock under 02333/9856-5 or by E-Mail under info@zwick-gmbh.de.

On our homepage under the menu item “Service” you will also find our download area. There you will find our current flyers, our image brochure and our data sheets.

We offer our customers and all interested parties various training courses, seminars and also webinars! Our experienced trainers, who are all our own employees, will explain you the structure of a valve, the maintenance of it and the application areas of our products.

Check-Up/ Inspection

Is the valve leaking? The actuator does not do what it should? If there are problems with our products, we will send an experienced technician to you to find a solution as quickly as possible.

Maintenance/ repair

We do not use external companies. Our in-house mechanics know our products very well and repair them directly on site! If this should not be possible, then we repair your valve also with us in the house.