ZERO-LEAKAGE.*

ALWAYS.

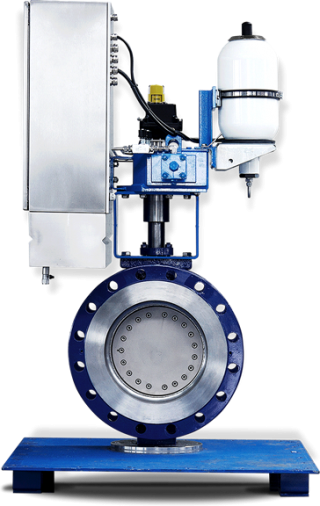

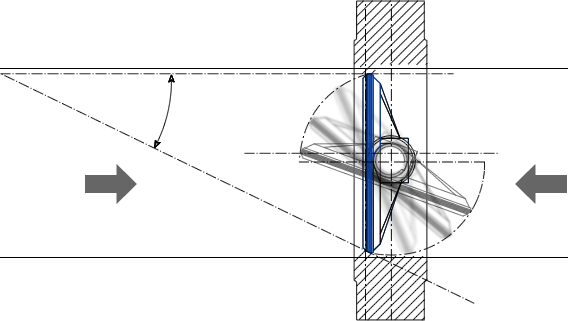

The number of unique technical attributes of the product, as the cone-in-cone seating design with the multiple laminations and the metal seat makes the series TRI-CON to an allrounder for many different industrial applications.

Zwick valves are used for industrial and exhaust gases, liquids, hot water or steam at lowest as well at high temperature zones up to 815°C. The TRI-CON is utilized extensively in the chemical, petro-chemical, oil & gas, offshore and district heating markets.